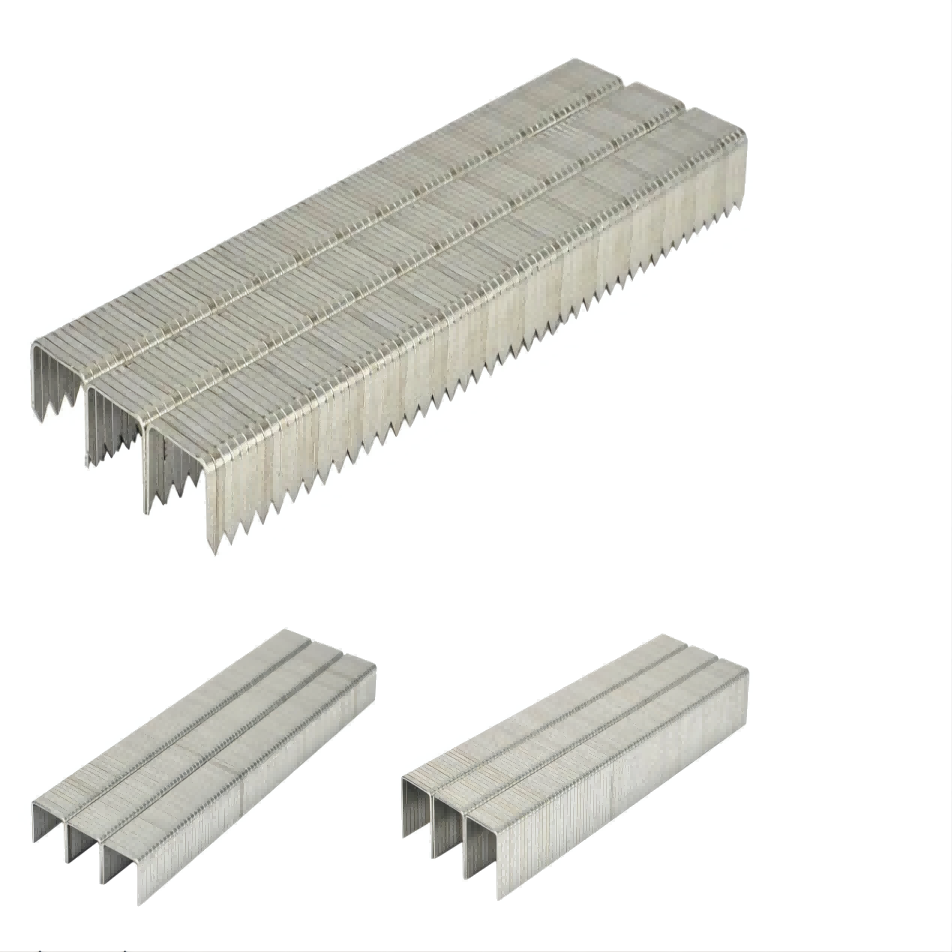

Karolo e Tloaelehileng ea tšepe ea tšepe ea Carbon e nang le Powder Coated

Mokhoa oa ho sebetsa:Ho fetola CNC, ho sila ka CNC, ho hatakela, ho phunya, ho sila etd.

Kalafo ea mocheso:Ho hloekisa mocheso, ho tloaeleha, ho tima, joalo-joalo.

Phekolo ea sefahleho:Anodize, Chromate, Electrolytic Plating, Nickel Plating, Galvanize, Tempered, Pente, Powder Coating, Polish joalo-joalo.

Kopo:Mechini ea Tlhahiso, Lisebelisoa tsa Elektroniki, Lisebelisoa tsa Indasteri, Motlakase, Kaho le Mokhabiso, Mabone, Lisebelisoa tsa Likoloi, Lipalangoang, Bongaka, Lihlahisoa tsa Khomphutha, Temo & Lijo joalo-joalo.

Sebopeho sa ho taka:PRO/E,CAD,E sebetsa ka thata,IGS,UG,CAM,CAE,PDF.

Tšebeletso:Ho latela litlhoko tsa bareki, e fana ka moralo oa tlhahiso, tlhahiso le ts'ebeletso ea tekheniki, nts'etsopele ea hlobo, le ts'ebetso ea ho fana ka ts'ebeletso e le 'ngoe.

Nako ea thomello:Matsatsi a 7-30

Ho paka:EPE foam/Rust proof paper/Filimi e otlollang/Mokotla oa polasetiki+lebokose

MOQ:E ka buisanoa

LBH

1.Melemo ea rona ke efe ho feta ba bang?

a).Lisebelisoa tsa kalafo tsa Stamping, Machining, Welding, Die casting le Surface li na le lisebelisoa tsa ho u fa litšebeletso le litharollo tsa rona tse ntlehali.

b).Lilemo tse 45 boiphihlelo.

c).Ho tsamaisoa ka nako.

e).Sistimi e thata ea ho laola boleng: tlhahlobo ea 100% pele e romelloa.

2.Ke bokhoni bofe ba tlhahiso ea k'hamphani ea hau?

a).Ho Merid, mesebetsi ea masela e kenyelletsa ho hatakela ka mokhoa o nepahetseng, ho taka ka botebo, ho koaleha hantle, ho phunya ka cnc, ho kobeha ha cnc, ho itšeha ka laser, ho itšeha lelakabe, ho sila ka cnc, ho phethoha ha cnc, ho kobeha ha tube, aluminium extruding, welding,

lefu la ho lahla, joalo-joalo.

b).Lisebelisoa tsa tšepe li kenyelletsa tšepe e sa hloekang, tšepe, tšepe ea carbon, tšepe ea selemo, aluminium, titanium, koporo, koporo, boronse joalo-joalo.

3.Ke lisebelisoa life tseo u nang le tsona?

a).Punch Press: 16T-500T.

b).Welding: Carbon dioxide welding, welding spot, tig welding, automated robotic welding.

c).Machining: CNC lathe le litsi tsa mochini, mechini e bobebe (ho cheka, ho sila le ho tlanya).

d).Die casting: 80T-500T.

e).Phekolo ea holim'a metsi: Setsi sa ho thunya, ho phunya, ho senya.

4.What finishes u ka fana ka?

Lithako tseo re ka fanang ka tsona ke ho roala phofo, ho penta, ho penta, ho belisoa, enamel e halikiloeng, linoko, le lisebelisoa tse ling tsa ho rala.

5.U ka tiisa boleng joang?

Lefapha la taolo ea boleng le haha moralo oa taolo pele le qala morero, tlhahlobo e tiileng e tla sebelisoa ho pholletsa le tlhahiso eohle.